The correlation analyses measures the linear relationship as well as the logarithmic relationship between the detection distance and the retroreflectivity of the pavement markings. The three conditions included: high (0.87 in/hr), medium (0.52 in/hr), and low (0.28 in/hr) flow rates, these rates were to simulate typical rainfall rates in the state of Texas. The researcher also incorporated detection distance values measured for the same 18 pavement marking samples under three different simulated rainfall conditions at night. Using three ASTM standard conditions resulted in three sets of retroreflectivity data, and variations of the continuous wetting standard produced an additional 11 sets of continuous wetting condition data.

The American Society for Testing and Materials (ASTM) has three standards for measuring the retroreflectivity of pavement markings under: dry (E-1710), recovery (E-2177), and continuous wetting conditions (E-2176). The researcher measured the retroreflectivity of 18 pavement marking samples under 14 different conditions. predictive performance of the resulting retroreflectivity values from the continuous wetting conditions. The researcher compared nighttime detection distance of pavement markings in simulated rain conditions and the retroreflectivity of the same pavement markings in several continuous wetting conditions. This thesis research investigated the predictive performance of pavement marking retroreflectivity measured under various conditions of continuous wetting. Selection and peer-review under responsibility of the organizing and review committee of IConDM 2013 It is found from this investigation that, the critical tribological performance influencing properties such as higher shear stability, low temperature stability and corrosion resistance are higher in chemically modified algal oil as compared to vegetable oil based metal working fluid. Further, secondary formulation technique of additives for improving the performance related parameters like extreme pressure wear resistance, corrosion resistance and thermal-oxidative stabilities was incorporated. The preliminary constituent of base oil is produced using solvent extraction method with optimized reaction parameters. In this work, micro algal oil, as a potential candidate for producing high performance metal working fluid is investigated. However, the harmful effects and high risk of life threatening occupational hazards to the machinists as well as causing environmental degradation is discouraging to continue its use in the near future.

Viscosity chemistry how to#

Finally, the article discusses how to use viscosity data to control your process.In metal working processes, the use of mineral, synthetic and semi-synthetic cutting fluids have gained widespread acceptance.

While it describes the three most-popular measurement methods, the article focuses on rotational viscometers - outlining the different components and how to choose the right instrument for a particular purpose. This article provides an overview of viscosity and how it is used in the quality-control laboratory as well as on the production floor. It is important to note, however, that the viscosity value obtained from a rotational viscometer depends on the shape and speed of rotation of the spindle. While this rheological property can be measured via several different devices (flow cups, capillary tubes, and rotational viscometers), rotational viscometers have become the most popular choice, as it is relatively straightforward to operate and requires minimal testing and clean-up time.

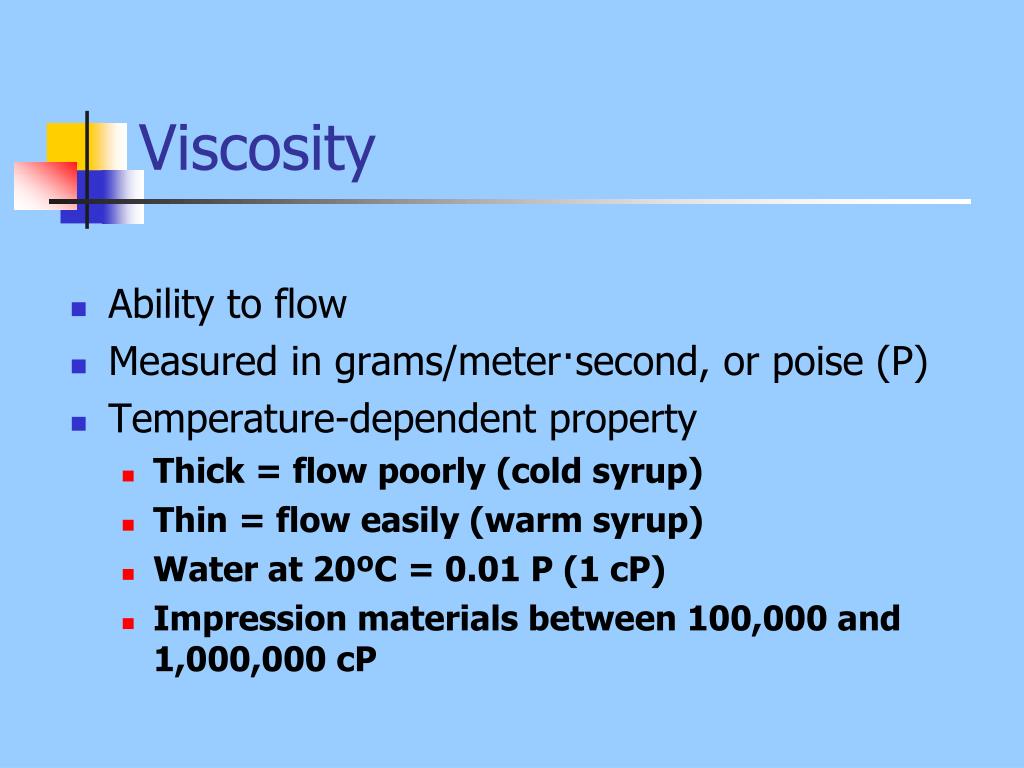

Viscosity - a measure of a fluid’s resistance to flow - is an important property of liquid and semi-liquid products that can be used for both process and product-quality control.

0 kommentar(er)

0 kommentar(er)